Select Product

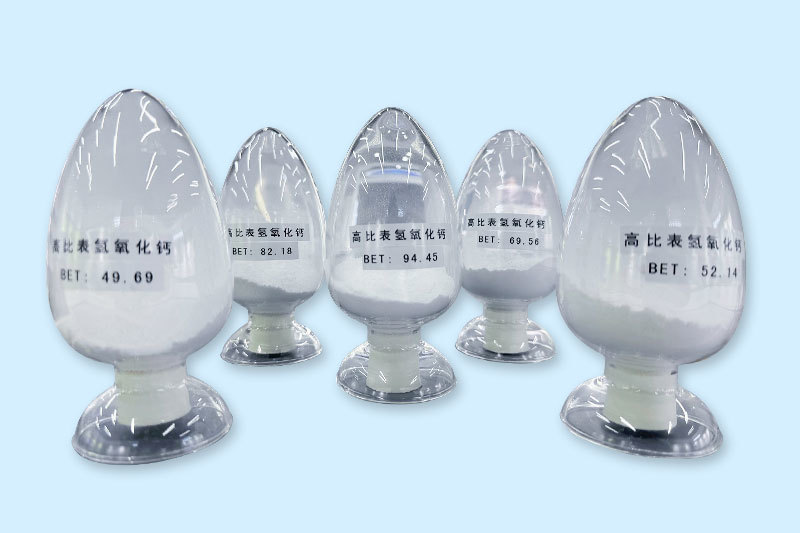

High-specific surface area calcium hydroxide

Summary:

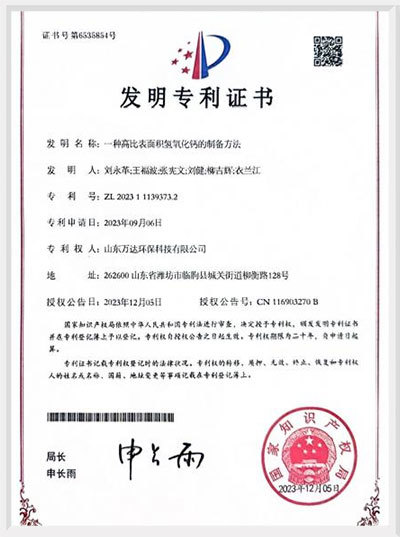

WD-HAD series high-efficiency desulfurizer is an independently developed product of Shandong Vanda Environmental Protection Technology Co., Ltd., with complete independent intellectual property rights. The product has a specific surface area of 50~100㎡/g, reaching a leading domestic level, and is widely used in flue gas desulfurization in industries such as steel, coking, industrial silicon, cement building materials, glass, ceramics, garbage power generation, and refractory materials.

Details

Product Overview

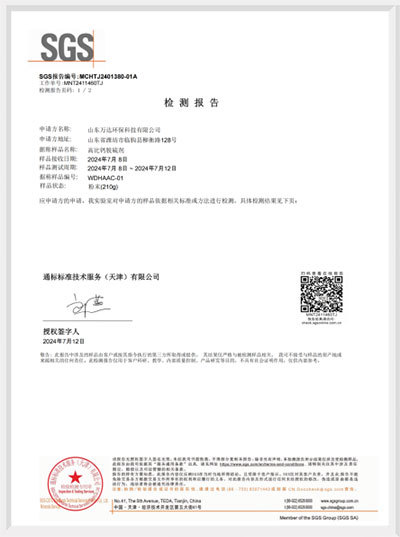

Shandong Vanda Environmental Protection Technology Co., Ltd.'s WD-HAD series high specific surface area calcium hydroxide has the characteristics of being porous, highly active, easily dispersed, and having a high utilization rate. It features fast reaction speed and high desulfurization efficiency in flue gas desulfurization, helping users quickly achieve flue gas desulfurization. A full range of product models are available to meet the needs of different flue gas desulfurization environments. The company currently has a 100,000-ton high specific surface area calcium hydroxide production base in Shandong and multiple cooperative factories nationwide, enabling mass production of high specific surface area calcium hydroxide. The product has obtained certification from the international SGS testing agency and has been highly recognized by many overseas customers.

Product Advantages

● Wide applicable temperature range (0-430℃); ● Small temperature drop; ● Good fluidity; ● High activity; ● High desulfurization efficiency; ● Low construction investment; ● Zero carbon emissions; ● Zero wastewater discharge; ● No water consumption; ● No hazardous waste generated; ● By-products can be recycled; ● This product also has a high removal rate for acidic gases such as hydrogen chloride and hydrogen fluoride.

Advantages of Calcium-Based Desulfurization

Sodium Bicarbonate Desulfurization

(1) Sodium bicarbonate desulfurization requires a high reaction temperature; the optimal desulfurization temperature for sodium bicarbonate is above 180°C, and no reaction occurs below 140°C;

(2) Large amount of sodium bicarbonate is required; removing one ton of sulfur dioxide requires 2.625 tons of sodium bicarbonate;

(3) The by-product of sodium bicarbonate desulfurization is sodium sulfate and sodium sulfite salt dust, which is difficult-to-handle hazardous waste and must be handled by a professional company;

(4) The sodium bicarbonate desulfurization system requires a 4-11kw grinder, increasing electricity costs, and there is noise pollution and dust pollution, resulting in a poor working environment;

(5) The product of sodium bicarbonate desulfurization is sodium salt, carbon dioxide, and water. Removing one ton of sulfur dioxide produces at least 1.375 tons of carbon dioxide, increasing carbon emissions and resulting in poor economic and social benefits;

High Specific Surface Area Calcium Hydroxide Desulfurization

(1) High specific surface area calcium hydroxide desulfurization has a wide applicable temperature range and can react efficiently in the range of 20°C~400°C;

(2) Small amount of high specific surface area calcium hydroxide is required; removing one ton of sulfur dioxide requires 1.156 tons of high specific surface area calcium hydroxide, which is 44% of the amount of sodium bicarbonate;

(3) The by-product of high specific surface area calcium hydroxide desulfurization is calcium sulfate and calcium sulfite dust, which is general solid waste and can be directly used as a supplementary material in cement, bricks, and other building materials.

(4) The high specific surface area calcium hydroxide desulfurizer is a 325-mesh ultrafine powder and does not require grinding; it can be used directly without noise or dust pollution;

(5) The product of high specific surface area calcium hydroxide desulfurization is calcium salt and water, which does not increase carbon emissions and has good economic and social benefits;

(6) High specific surface area calcium hydroxide can directly replace sodium bicarbonate in sodium bicarbonate desulfurization systems.

Technical Indicators

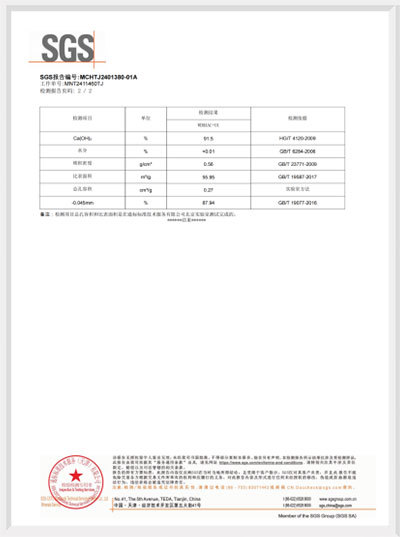

| Appearance | White powder |

| Ca(OH)₂ 2 Content | 85~99% |

| Water content | 0.1~3wt% |

| Particle size distribution (325 mesh screening rate) | 90~99% |

| Bulk density | 0.4~0.65g/mL |

| BET specific surface area | 40~100m²/g |

| SO₂ removal efficiency | ≥ 97% |

| Pore volume | >0.2cm³/g,nano-scale pore size 2~100nm |

Successful Cases

The high specific surface area calcium hydroxide produced by our company has been used for a long time in dry desulfurization applications under complex operating conditions in various flue gases from coal-fired lime kilns, metallurgical aluminum smelting furnaces, coke ovens, and garbage power generation plants. The desulfurization efficiency can reach more than 97% (experimental report examples 97.33%~99.7%), and strategic cooperation projects have been signed with many companies.

A certain lime plant in Yuzhou

The catalytic cracking unit uses a highly efficient calcium-based dry desulfurization agent to achieve synergistic removal of multiple pollutants such as SO₂, NOx, and particulate matter in flue gas, reducing flue gas pollution.

A certain refractory materials plant in Shandong

The amount of highly efficient calcium-based desulfurization agent used has been reduced by about 35%. Previously, the amount of calcium-based desulfurization agent used from other manufacturers was 320 kg, but now the amount used with our company's product is only 200 kg.

Aluminum smelting furnace project of a certain aluminum plant in Linqu

Compared with calcium-based desulfurization products from other suppliers, our highly efficient calcium-based dry desulfurization agent reduces daily usage by about 50% (from 80-100 kg to 40-50 kg) and costs by about 50%, and the actual SO₂ emission value is <5mg/Nm³, far lower than the local standard ≤50mg/Nm³.

Other Products

Inquire Now

Leave a message to get a lower quotation for environmental protection equipment!