Application Industry

Glass factory

The glass furnace flue gas treatment project uses a highly efficient calcium-based dry desulfurization agent to achieve highly efficient removal of SO2 from the flue gas, while simultaneously reducing pollutants such as dust and HCl in the flue gas, and improving the quality of flue gas emissions.

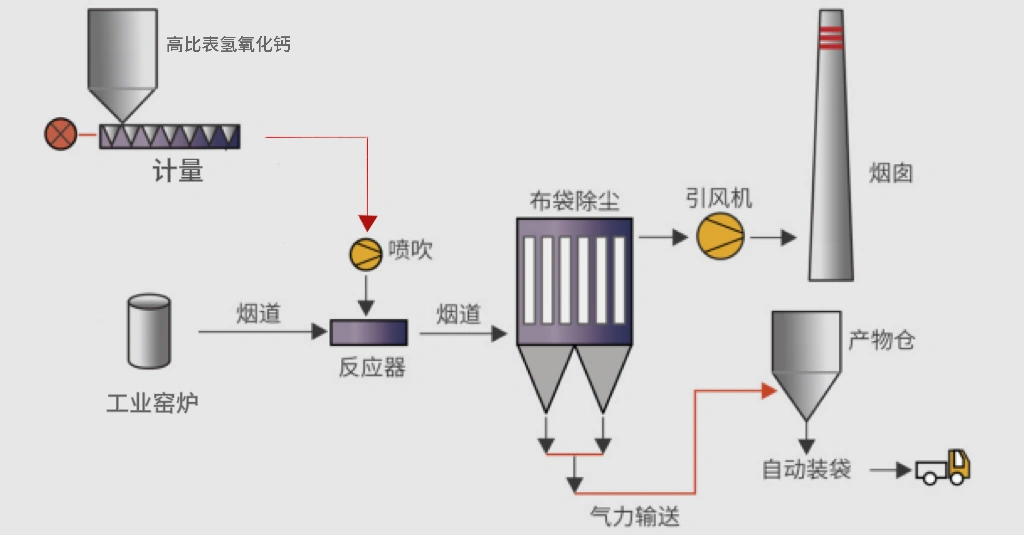

Efficient calcium-based desulfurizer dry desulfurization process

Desulfurizing Agent System

This system mainly includes unloading, powder silo, metering module, and conveying system. High specific surface area calcium hydroxide powder is sent into the powder silo from a ton bag via an electric hoist, and then through the metering module at the bottom of the powder silo, it is conveyed to the desulfurization flue or desulfurization tower via a blower.

Desulfurization Reaction System

This system mainly includes the desulfurization flue or desulfurization tower. The high specific surface area calcium hydroxide powder is injected into the desulfurization system, where it undergoes a neutralization reaction with SO2, thereby removing SO2 and generating reaction products such as CaSO4 and CaSO3. These dry products enter the baghouse dust collector with the flue gas.

Desulfurization Product Collection

This system mainly includes a baghouse dust collector and desulfurization product collection. The gypsum powder generated after desulfurization is collected by the baghouse dust collector after dry desulfurization, and is centrally processed together with the dust through the ash conveying system. The main components of the desulfurization products are CaSO4 and CaSO3, which are not hazardous waste and can be treated together with ordinary dust. The baghouse dust collector can ensure that the dust concentration in the flue gas is within the design index.

Qingdao Glass Products Co., Ltd.

Flue Gas Temperature

~ 220℃

Project Type

Baking soda improves calcium ratio

Process Flow

Glass furnace flue gas → waste heat boiler → high-calcium dry desulfurization (220℃) → baghouse dust collector → SCR denitrification → fan → chimney

Results

(1) SO2 concentration reduced from 1200mg/m3 to <50mg/m3

(2) Original sodium bicarbonate usage was 6t/day. After switching to high-calcium, usage and operating costs have been significantly reduced.

(3) Costs for handling sodium bicarbonate desulfurization solid waste have been saved.