28

2025

-

06

High-Specific-Surface Calcium Hydroxide: The "Game-Changer" in Flue Gas Desulfurization, Ushering in a New Era of Ultra-Low Emissions

Author:

Against the backdrop of increasingly stringent environmental policies and industrial emission standards, flue gas desulfurization (FGD) technologies face dual challenges of efficiency and cost. Traditional desulfurization methods often suffer from high investment, high energy consumption, and difficulties in handling by-products. High-specific-surface calcium hydroxide (WD-HAD Series High-Efficiency Desulfurizer) developed by Shandong Vanda Environmental Technology Co., Ltd., with its breakthrough physicochemical properties, is bringing revolutionary solutions to the field of flue gas treatment, demonstrating broad application prospects.

I. Technological Breakthrough: The "Magic" of High Specific Surface Area

The core advantages of high-specific-surface calcium hydroxide lie in its significantly enhanced physical activity:

* Enormous Reaction Interface: BET specific surface area as high as 50-100 m²/g (far exceeding ordinary calcium-based desulfurizers), providing massive reactive sites.

* Developed Pore Structure: Pore volume >0.25 cm³/g, forming efficient gas diffusion channels.

* High Purity and Fineness: Ca(OH)₂content >90%, passing rate at 325 mesh >85%, ensuring uniform and thorough reaction.

These characteristics directly translate into exceptional desulfurization performance:

* Ultra-High Efficiency: SO₂removal efficiency ≥97%, easily meeting the strictest "ultra-low emission" standards (e.g., required in glass, ceramics industries).

* Broad Temperature Range Adaptability: Efficient reaction across a wide flue gas temperature range of 0℃to 430℃, solving the pain points of traditional wet methods being temperature-sensitive and prone to condensation and blockage.

* Deep Purification: Excellent removal rates for acidic gases such as HCl and HF, enabling synergistic control of multiple pollutants.

II. Economic Benefits: The "Cost-Effectiveness Tool"

Compared to traditional desulfurization technologies (especially wet methods), the high-specific-surface calcium hydroxide dry FGD process offers significant cost advantages:

* Lower Initial Investment: Simplified process flow, eliminating the need for complex water treatment systems and anti-corrosion measures, leading to significantly reduced construction investment.

* Optimized Operating Costs: Comprehensive desulfurization costs can be reduced by approximately 30%. For large enterprises, annual direct desulfurization cost savings can reach 1.5 - 2 million RMB.

* Resource Utilization Potential: Desulfurization by-products (mainly calcium sulfate, etc.) are stable and easy to utilize as resources (e.g., building material raw ingredients), with no hazardous waste generation, avoiding secondary pollution and disposal costs.

* Zero Water Consumption & Zero Carbon Emissions: No water resource consumption, no wastewater discharge. The process itself generates no direct carbon emissions, aligning with the "Dual Carbon" goals.

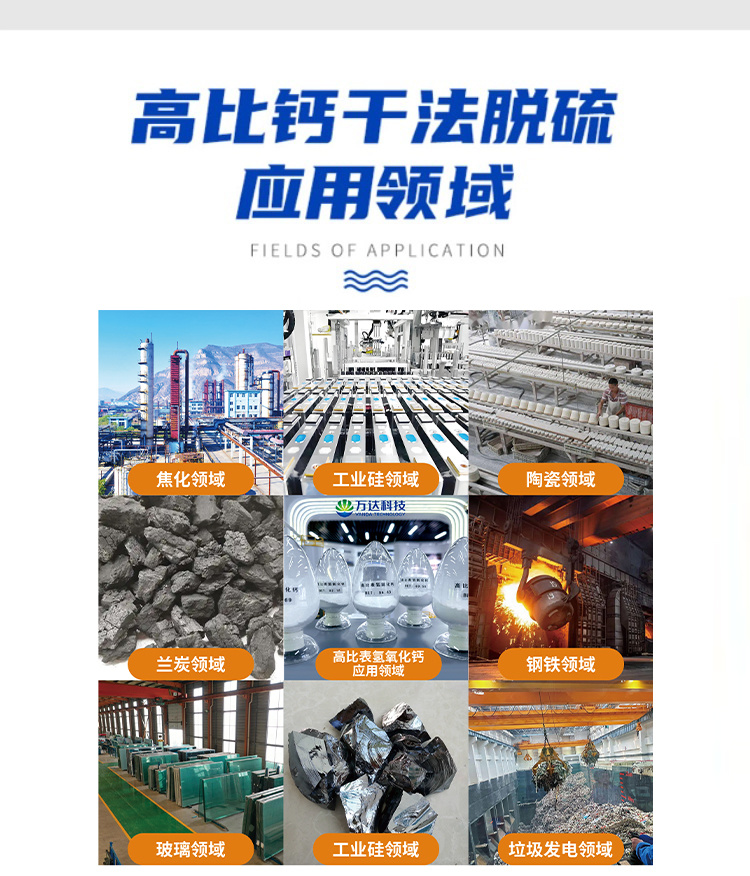

III. Application Prospects: The "Key" to Empowering Multiple Industries

The excellent characteristics of high-specific-surface calcium hydroxide dry FGD make it universally applicable across numerous industrial sectors:

* Traditional High-Emission Industries: Successfully applied in industries like glass, ceramics, refractories, cement, steel, coking, carbon, serving as a key technology for achieving ultra-low emissions.

* Emerging Energy & Materials Fields: Its advantages of broad temperature adaptability and high-efficiency purification are prominent in rapidly developing sectors such as photovoltaics (industrial silicon, sodium silicate), new energy batteries (lithium battery materials), and waste-to-energy.

* Complex Process Scenarios: An ideal choice for industrial facilities with large flue gas fluctuations, wide temperature ranges, or located in water-scarce regions.

IV. Leading Enterprise: The Innovation-Driven "Engine"

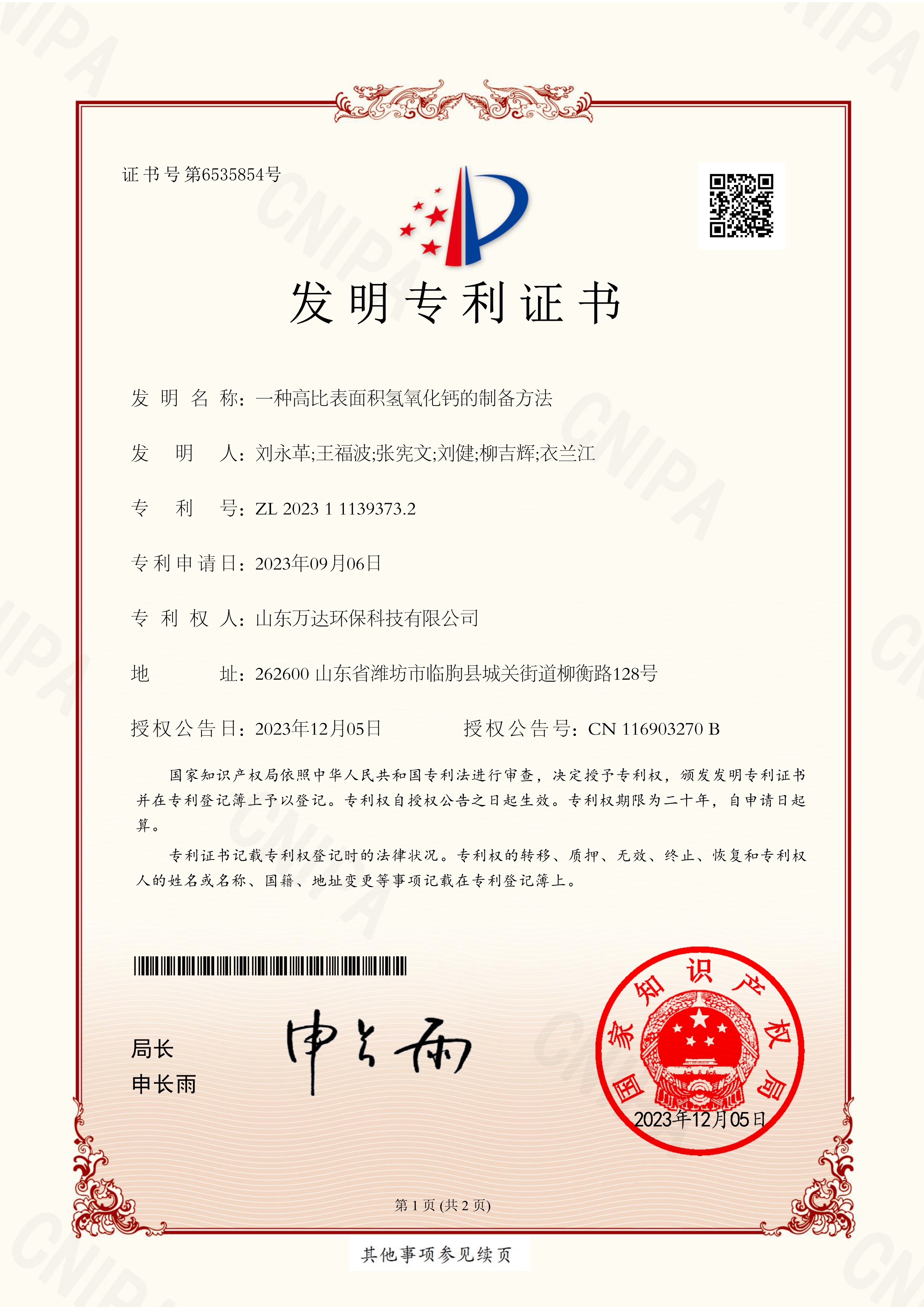

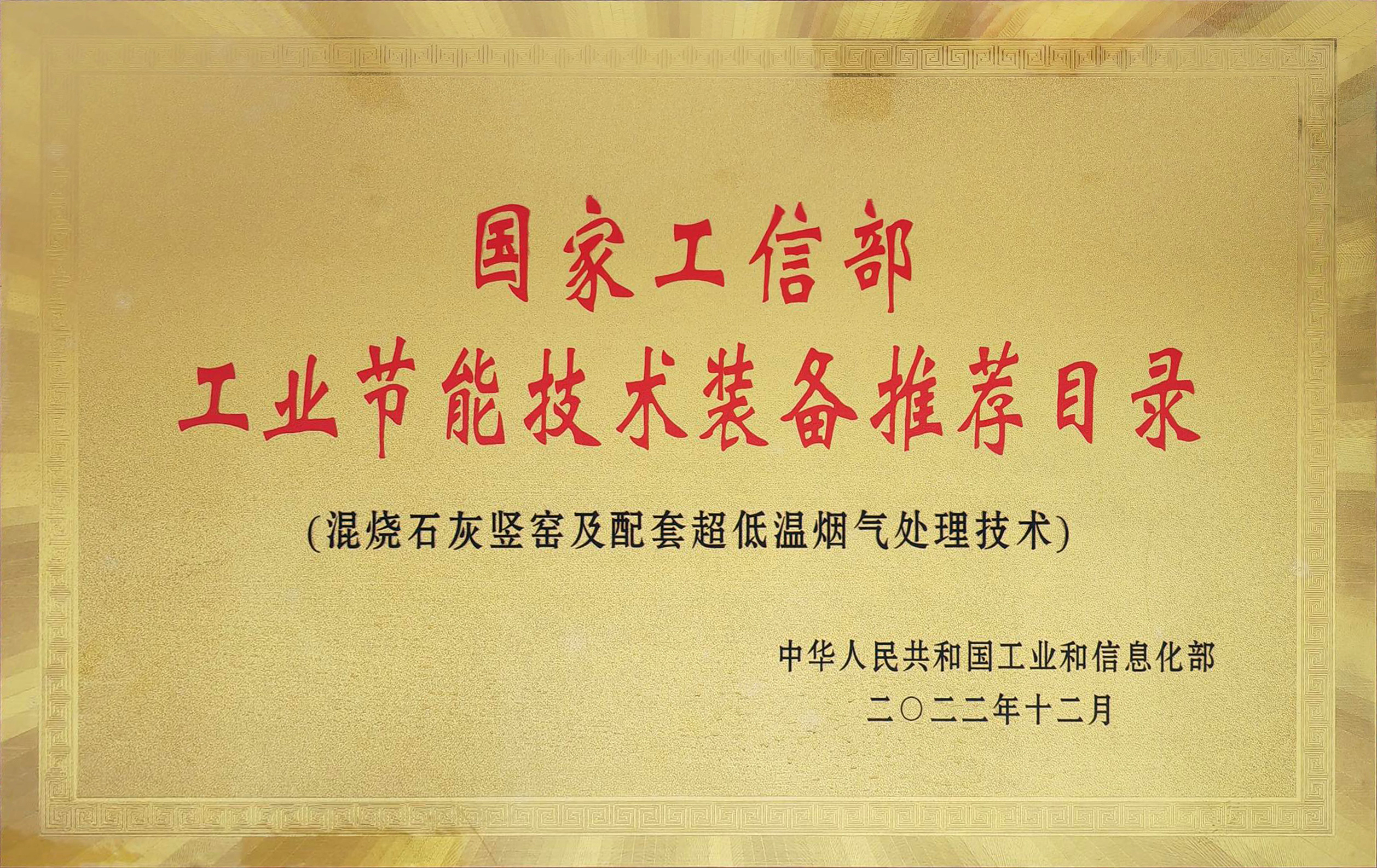

Shandong Vanda Environmental Technology, as a National-Level Specialized and Sophisticated "Little Giant" Enterprise and a "Gazelle Enterprise" in this field, has laid the cornerstone for application prospects with its technological strength:

* Core Technology Independence: Possesses complete independent intellectual property rights for the WD-HAD Series High-Efficiency Desulfurizer, with product specifications reaching internationally leading levels.

* Scale Guarantee: Possesses a 100,000 tons/year single-line production capacity, ensuring stable market supply.

* Standard Setter: Led or participated in formulating multiple industry standards. Products are listed in the MIIT Recommended Catalog of Energy-Saving and Environmental Protection Products.

* Flexible Cooperation Models: Offers various models including direct product sales, technical support, equipment supply, and even cooperative plant construction to accelerate technology adoption.

Conclusion: The "Ideal Calcium-Based Choice" for a Green Future

High-specific-surface calcium hydroxide dry FGD technology, with its ultra-high efficiency, outstanding cost-effectiveness, wide adaptability, and environmental friendliness, has successfully broken through the bottlenecks of traditional flue gas treatment. Driven by the "Dual Carbon" strategy and ultra-low emission policies, this technology has not only become a "must-have" for the green transformation of traditional industries like glass, ceramics, and steel, but will also shine in emerging fields such as photovoltaics, lithium batteries, and waste-to-energy. Continuous innovation and scaled application by enterprises represented by Shandong Vanda Environmental Technology are propelling high-specific-surface calcium hydroxide from a "technological tool" towards "market mainstream," opening up a new path of efficient, economical, and sustainable green development for industrial flue gas treatment. Its application prospects are limitless.

Next

Next

Latest News

2025-08-02

Vanda Tech: Leading Green Industry with High Specific Surface Calcium Hydroxide Desulfurization Technology

In today's increasingly stringent environmental landscape, efficient and clean flue gas desulfurization technology has become an industrial necessity. Shandong Vanda Environmental Protection Technology Co., Ltd. (Vanda Tech) is providing leading desulfurization solutions for industries such as steel, coking, and new energy, leveraging its independently developed WD-HAD Series High Specific Surface Calcium Hydroxide Desulfurizer and advanced production lines.

2025-07-07

High Specific Surface Area Calcium Hydroxide: A Powerful Desulfurization Solution Driving Green Upgrading in the Coking Industry

Coking production is a crucial link in the steel industry chain. However, the generated flue gas contains high concentrations of sulfur dioxide (SO₂), posing serious hazards to the environment and equipment. Traditional desulfurization technologies often face challenges such as insufficient efficiency, high operating costs, or secondary pollution. WD-HAD Series High-Efficiency Desulfurizer, independently developed by Shandong Wanda Environmental Technology Co., Ltd., provides an innovative, efficient, economical, and environmentally friendly solution for flue gas treatment in the coking industry, leveraging the exceptional performance of its core component—High Specific Surface Area Calcium Hydroxide.

2025-06-28

Innovative Application of High-Specific-Surface-Area Calcium Hydroxide in Flue Gas Desulfurization for the Steel Industry

Against the backdrop of severe environmental pressure facing the steel industry, the WD-HAD Series High-Specific-Surface-Area Calcium Hydroxide Desulfurizer, independently developed by Shandong Vanda Environmental Technology Co., Ltd., is becoming a core solution in the field of flue gas purification, relying on its internationally leading technical indicators (specific surface area: 50-100 m²/g).

2025-06-28

High-Specific-Surface Calcium Hydroxide: The "Game-Changer" in Flue Gas Desulfurization, Ushering in a New Era of Ultra-Low Emissions

Against the backdrop of increasingly stringent environmental policies and industrial emission standards, flue gas desulfurization (FGD) technologies face dual challenges of efficiency and cost. Traditional desulfurization methods often suffer from high investment, high energy consumption, and difficulties in handling by-products. High-specific-surface calcium hydroxide (WD-HAD Series High-Efficiency Desulfurizer) developed by Shandong Vanda Environmental Technology Co., Ltd., with its breakthrough physicochemical properties, is bringing revolutionary solutions to the field of flue gas treatment, demonstrating broad application prospects.

2025-03-25

Vanda Environmental Protection Technology Desulfurizer - High Specific Surface Area Calcium Hydroxide (High Activity Calcium Hydroxide)

The desulfurization absorption and product treatment of the high-activity, high-specific surface area calcium hydroxide desulfurization (powder) technology are carried out in a dry state.